DTF vs HTV: Which Is Right for Your T-Shirt Business?

Is DTF or HTV the best solution for your t-shirt business?

If you’re thinking about starting a t-shirt business from home, or you already have one and you’re considering switching things up, this is a decision almost everyone faces at some point.

In this post, I’m breaking down iron-on vinyl (HTV) versus DTF (Direct to Film) in a very practical way. I’ll walk you through:

the design process for each

how long they take to make

how they apply to a t-shirt

a real wash test

the pros and cons

and a realistic startup cost comparison

By the end, you should have a much clearer idea of which option makes the most sense for your business.

Continue reading below, or take a look at my video comparison…

The content below contains affiliate links and we may earn a commission if you shop through them, however this won't cost you anything, it just helps us to keep the site running for free. For more information on affiliate links, see the disclosure here.

The Setup: What I’m Using

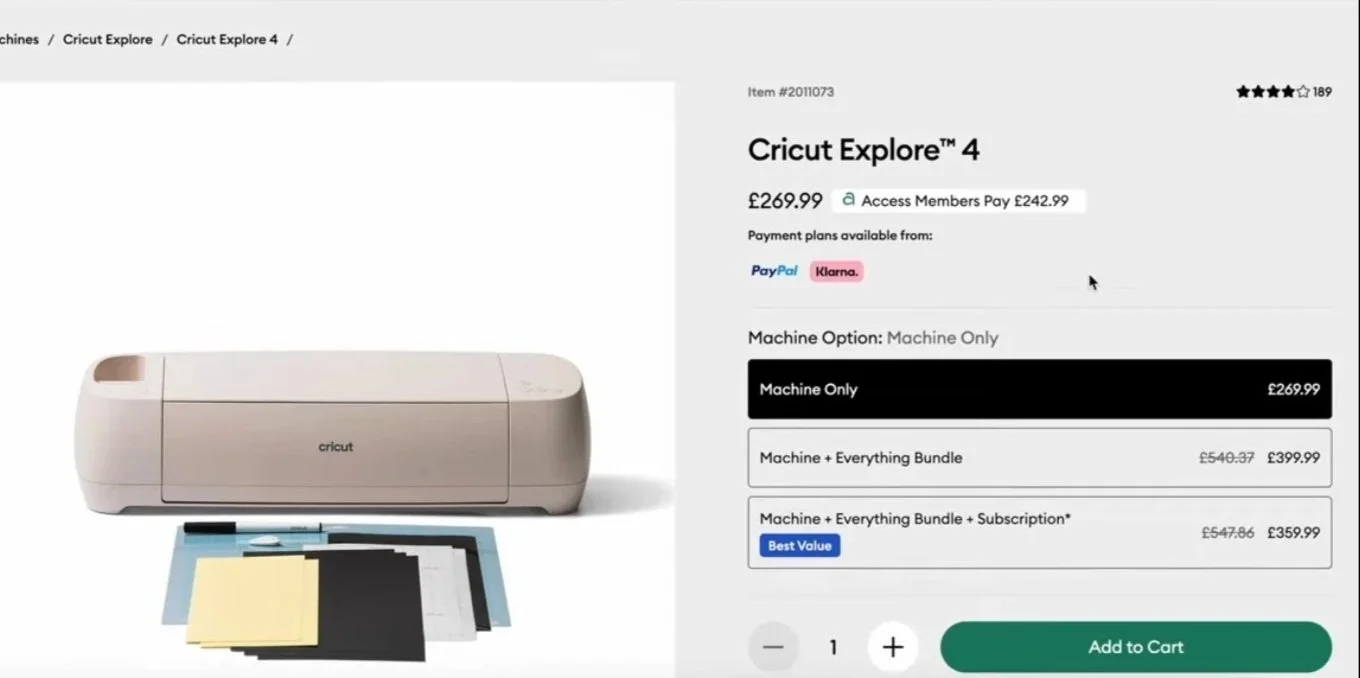

For HTV, I’m cutting vinyl on my Cricut (though the process applies to any cutting machine).

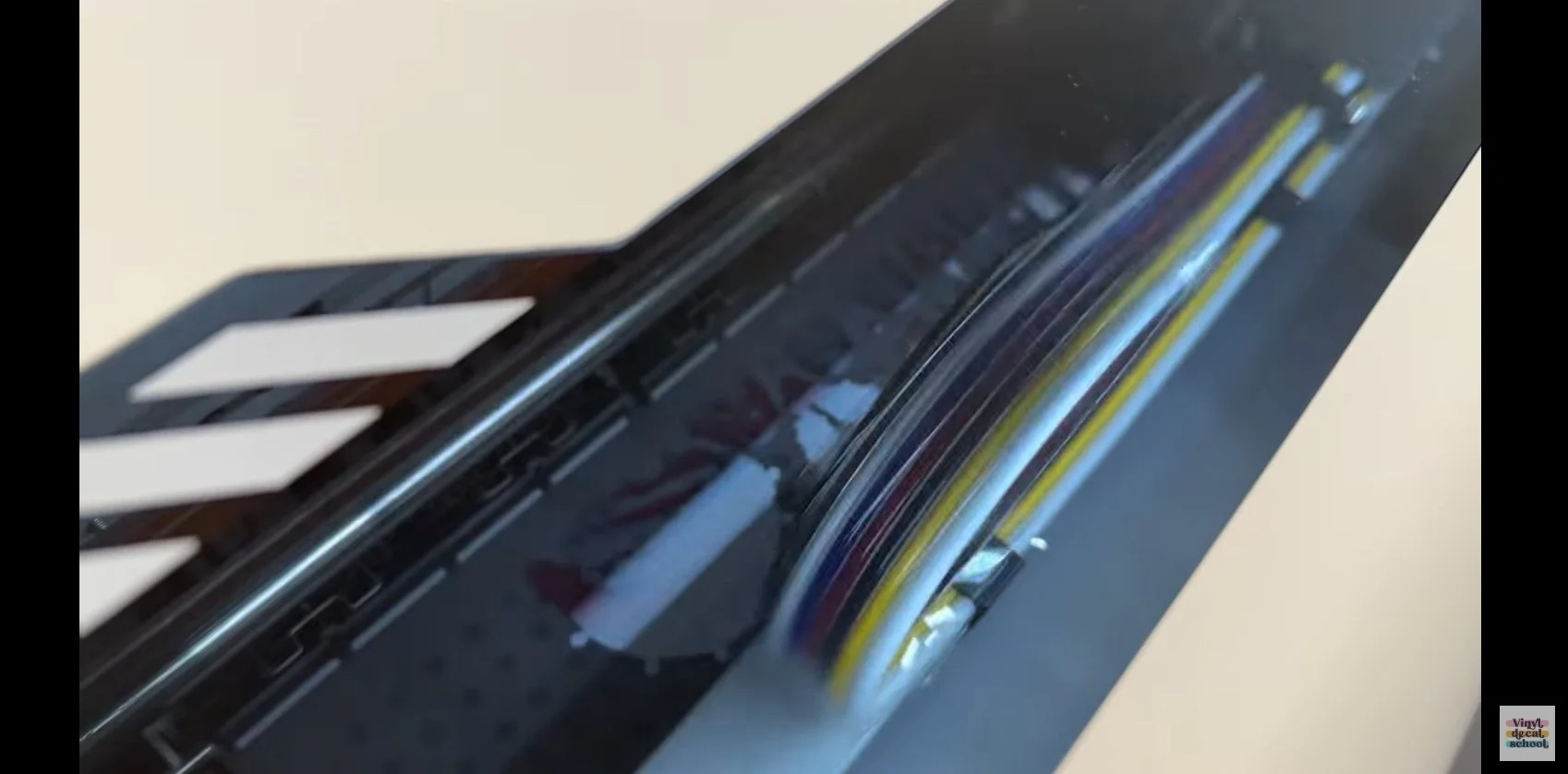

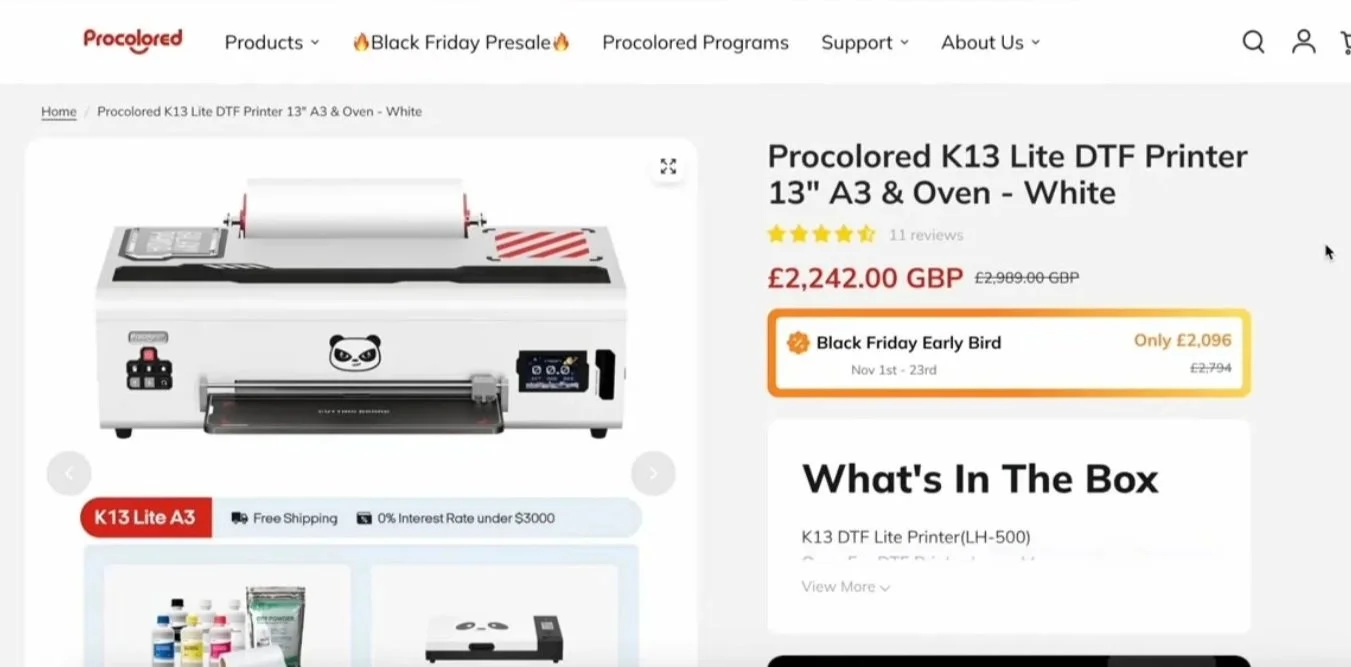

For DTF, I’m printing with the Procolored K13 Lite, which I was kindly gifted. It’s designed as a beginner-friendly DTF printer, with:

an easy-maintenance printhead

automatic cleaning technology

fewer technical steps to learn

This comparison is sponsored by Procolored, but everything below is my honest, real-world experience with both materials so you can make your own decision.

Design Process: HTV vs DTF

Designing for HTV (Iron-On Vinyl)

When designing for HTV, your options are more limited.

You can’t use full-colour designs, so you’re generally looking for:

single-colour SVGs

or layered designs (one colour per layer)

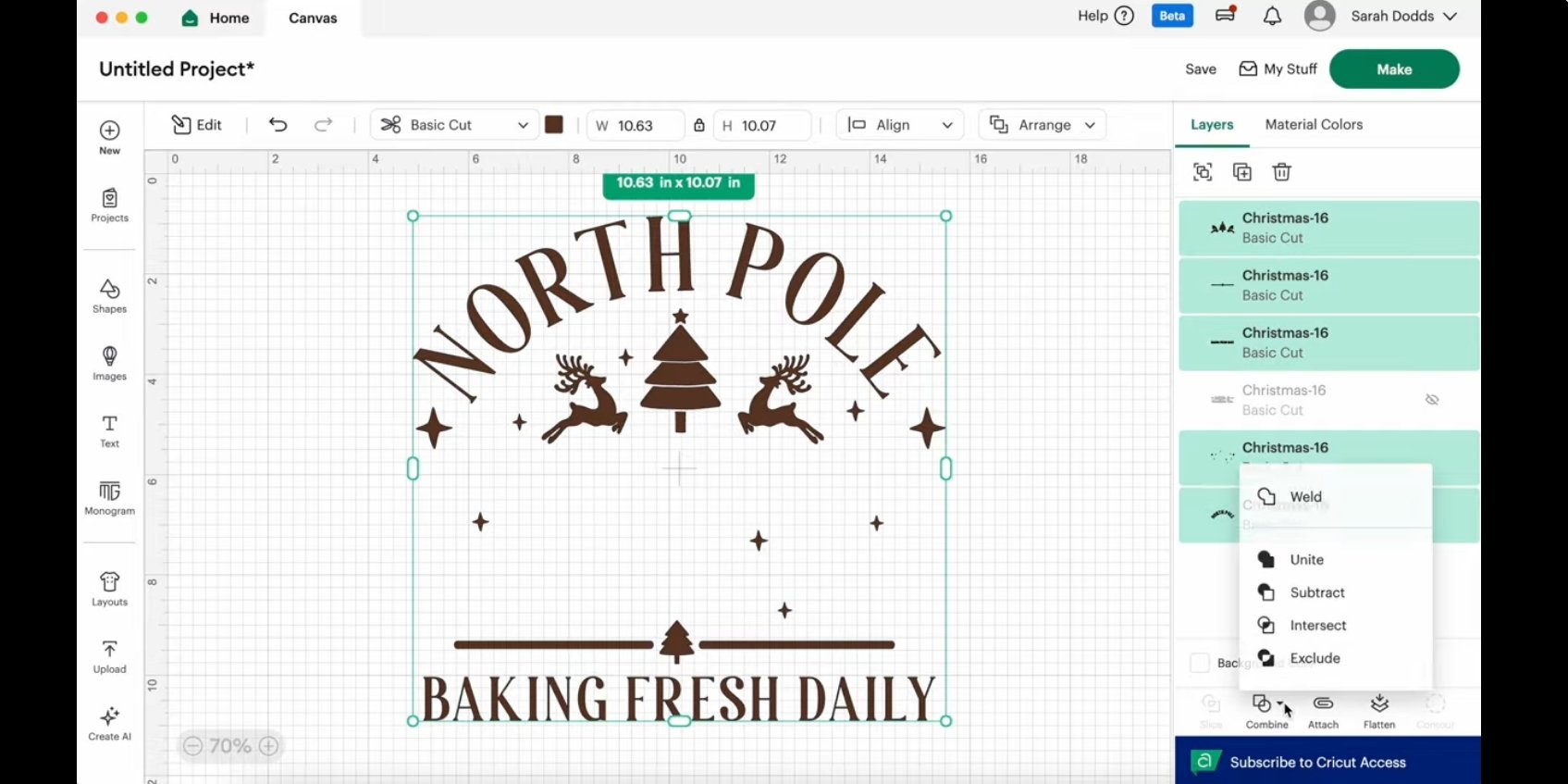

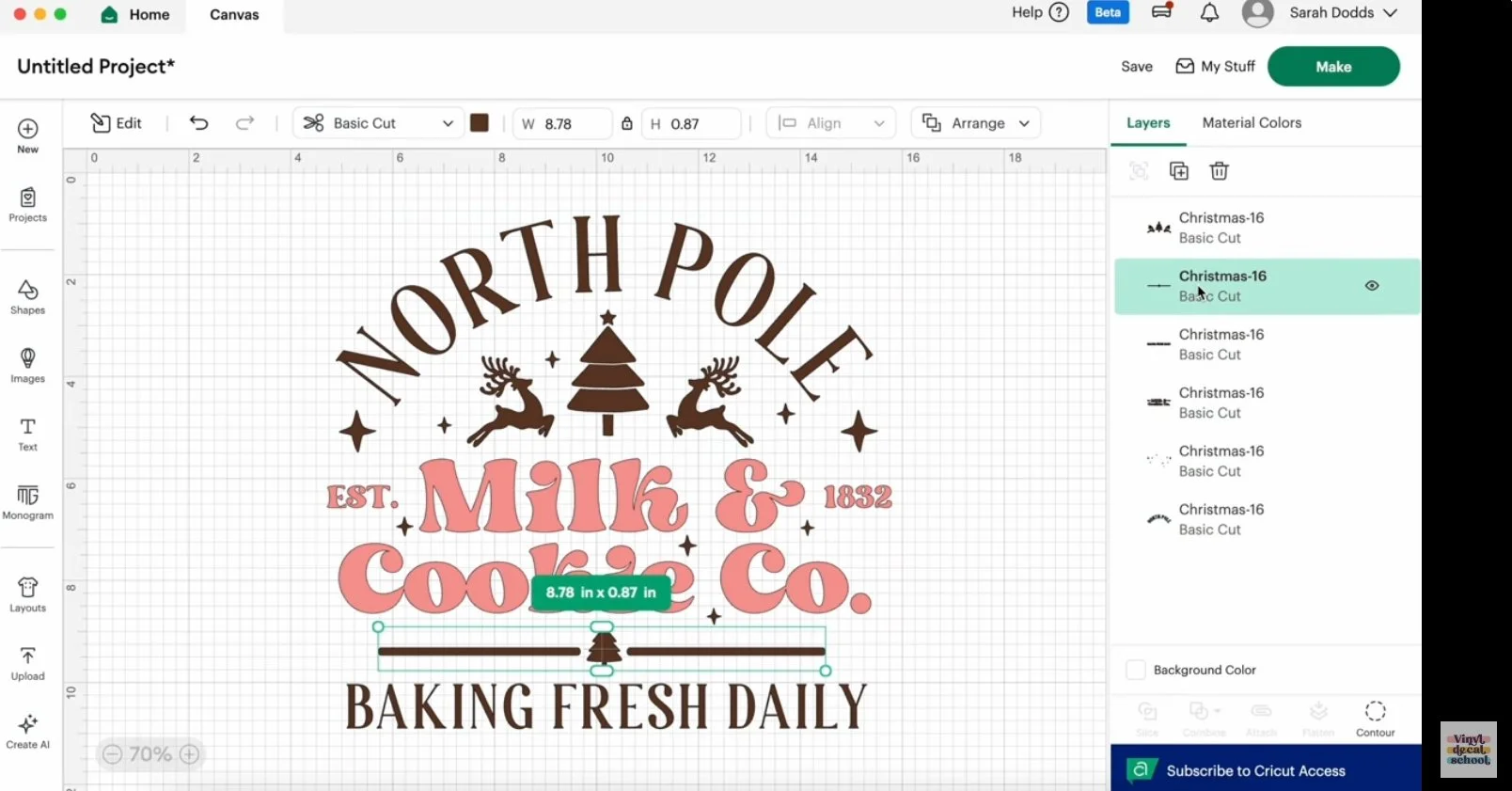

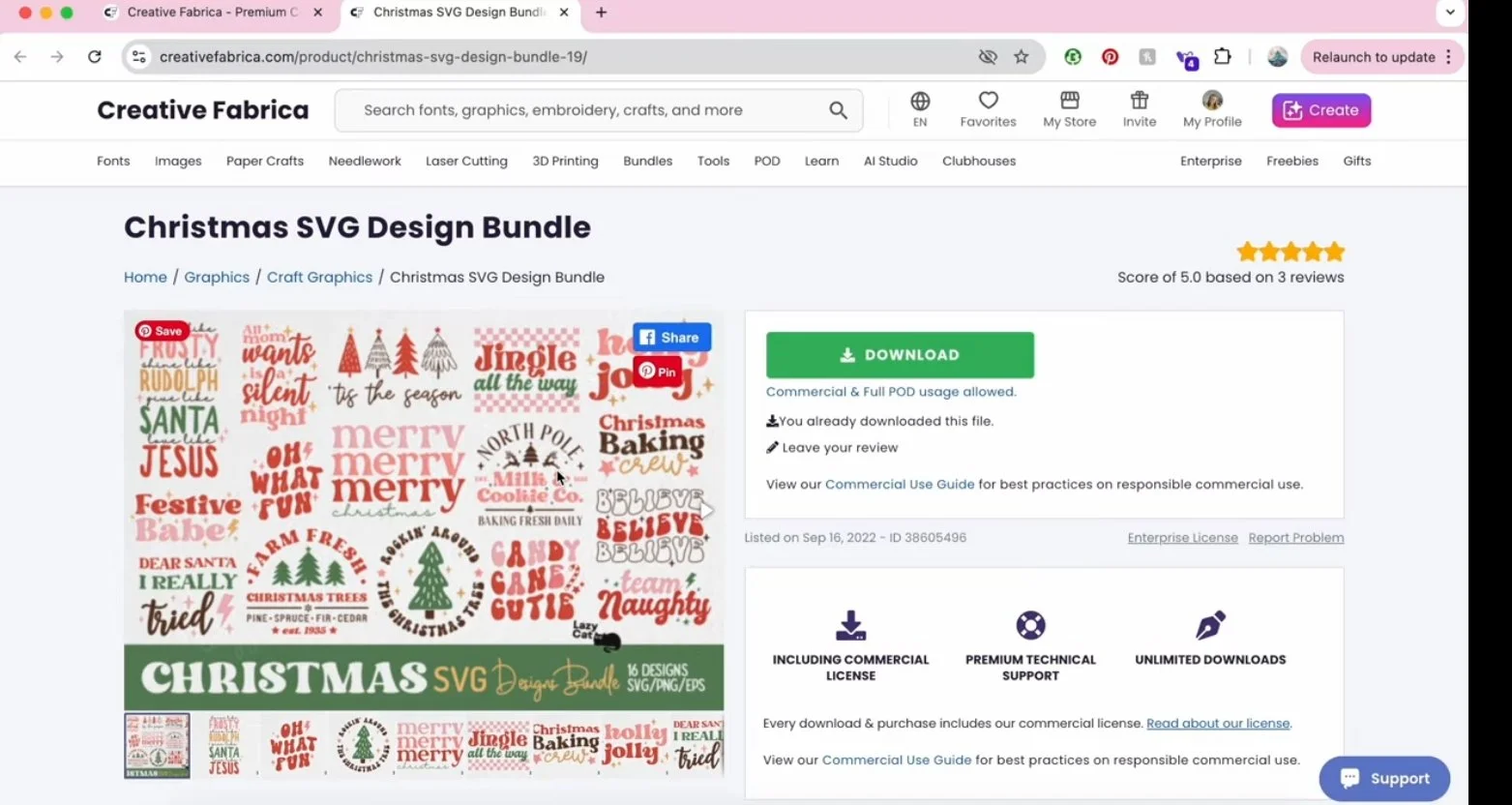

I downloaded a layered SVG bundle and uploaded it into Design Space, although you could also:

design directly in the software

or use designs from Cricut Access

Layered designs often need:

ungrouping

cleaning up

merging shapes

assigning correct colours

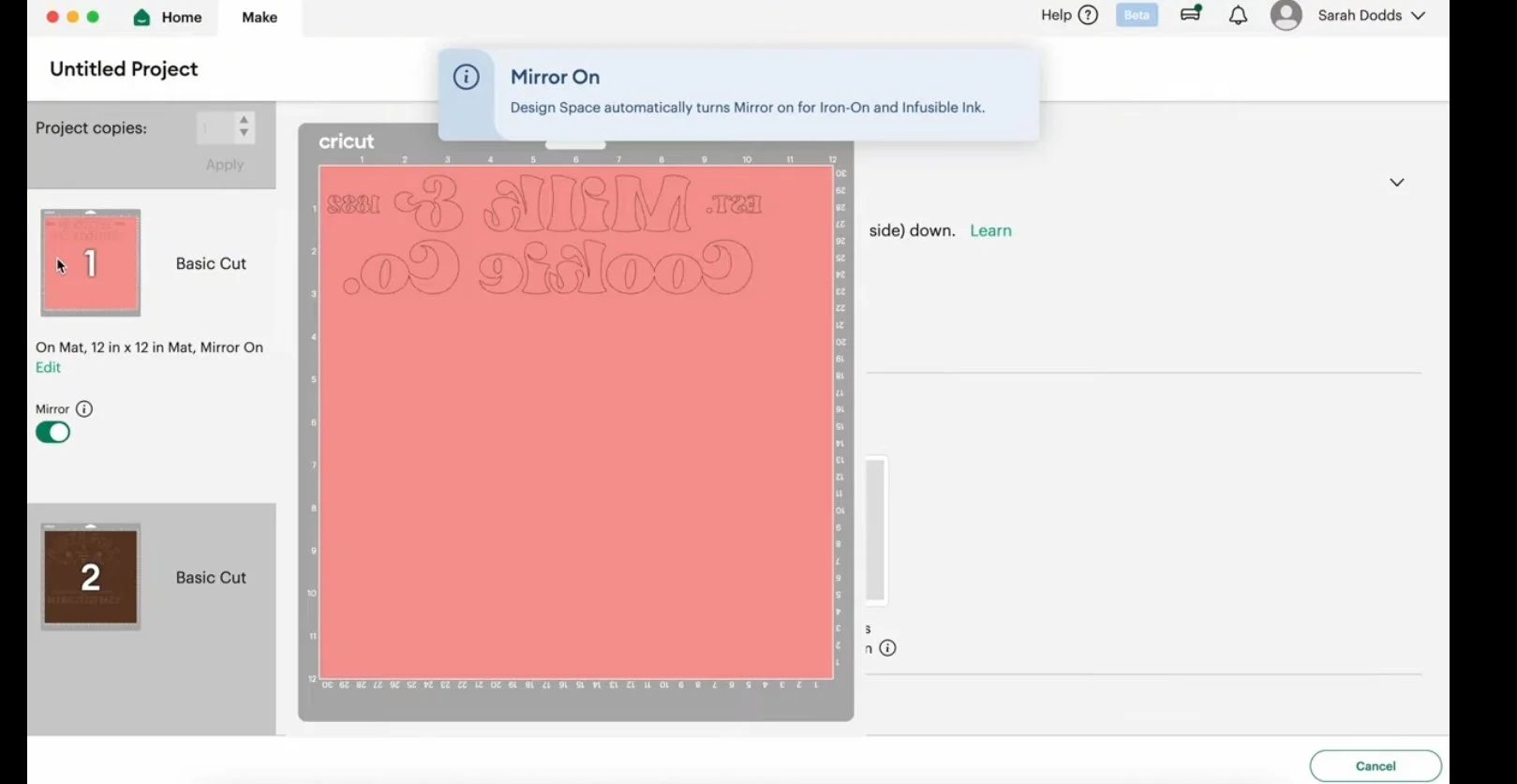

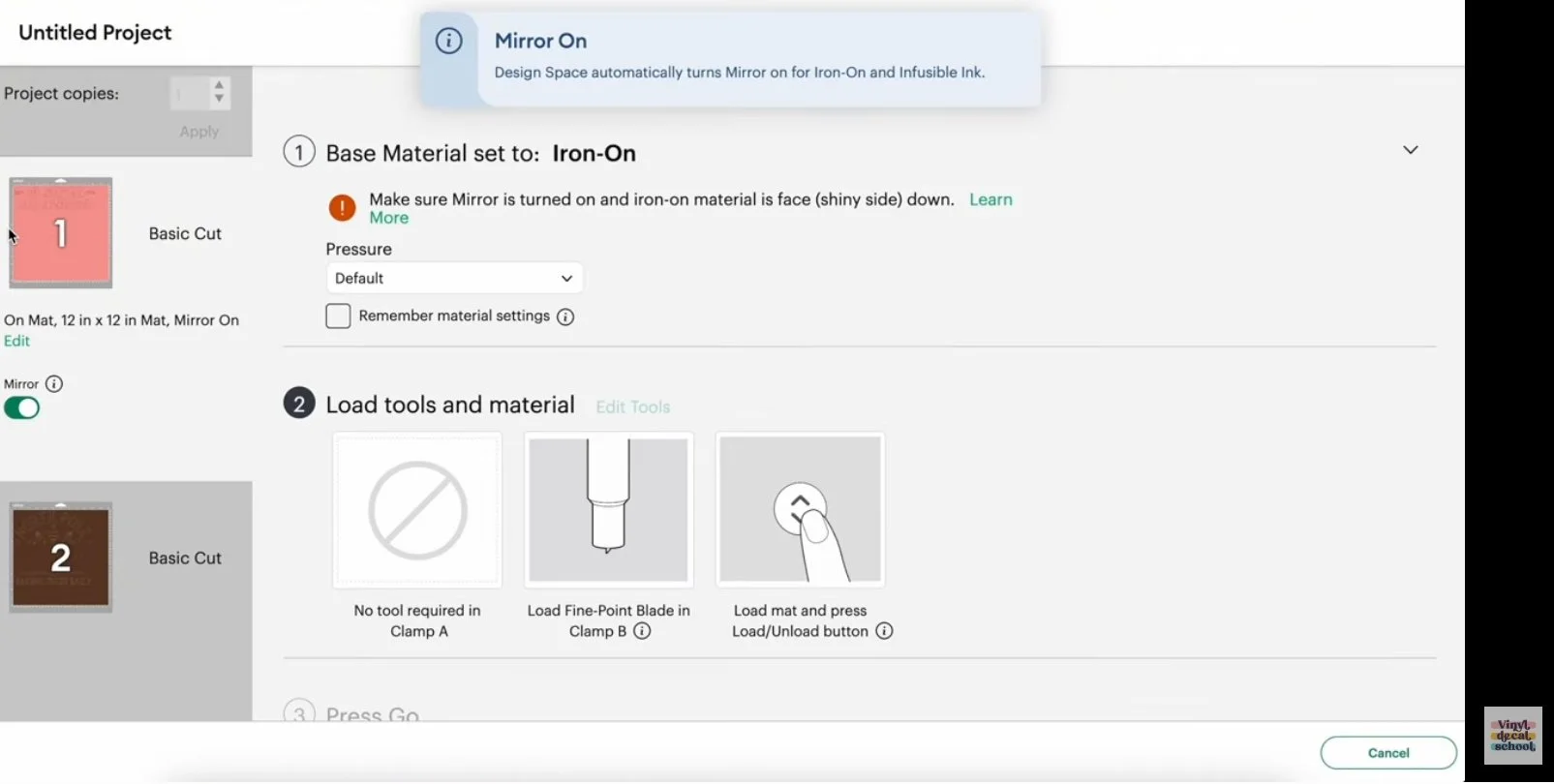

Once ready, you must:

choose the correct cut setting

mirror the design before cutting

This setup stage can take time, especially with complex designs.

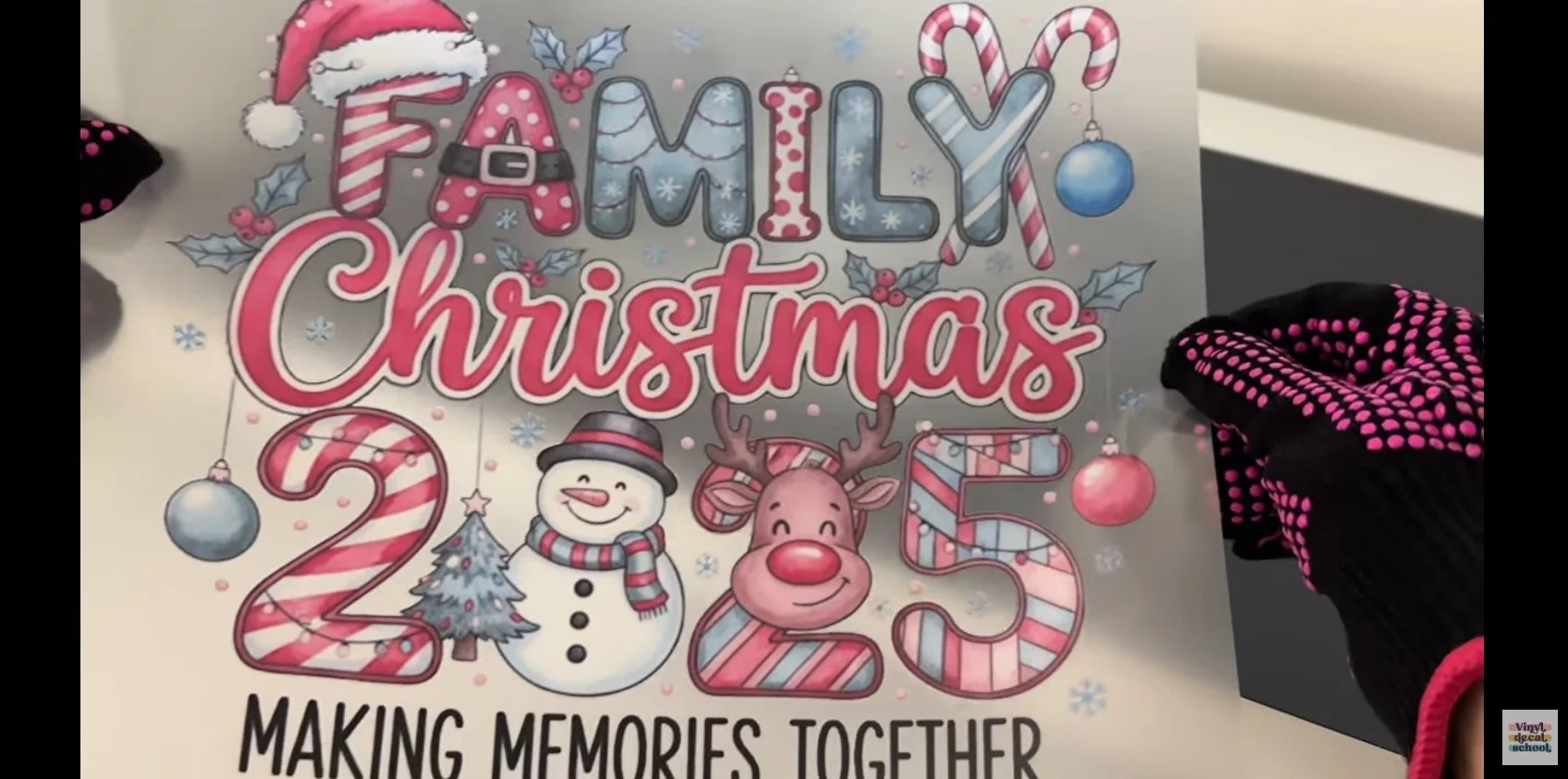

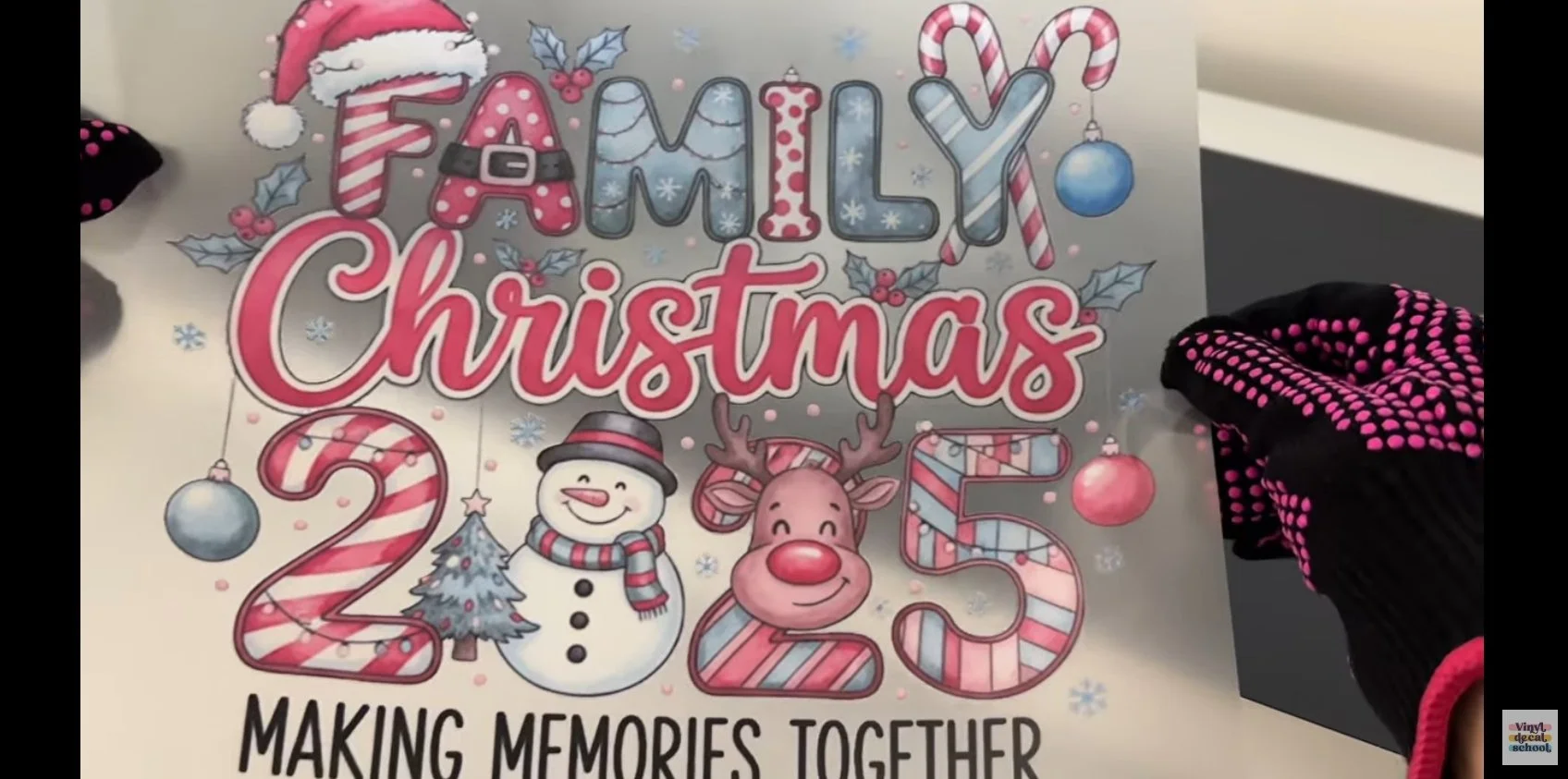

Designing for DTF

DTF offers far more creative freedom.

You can use:

full-colour designs

gradients

illustrations

detailed graphics

The only requirement is that your design is a transparent PNG.

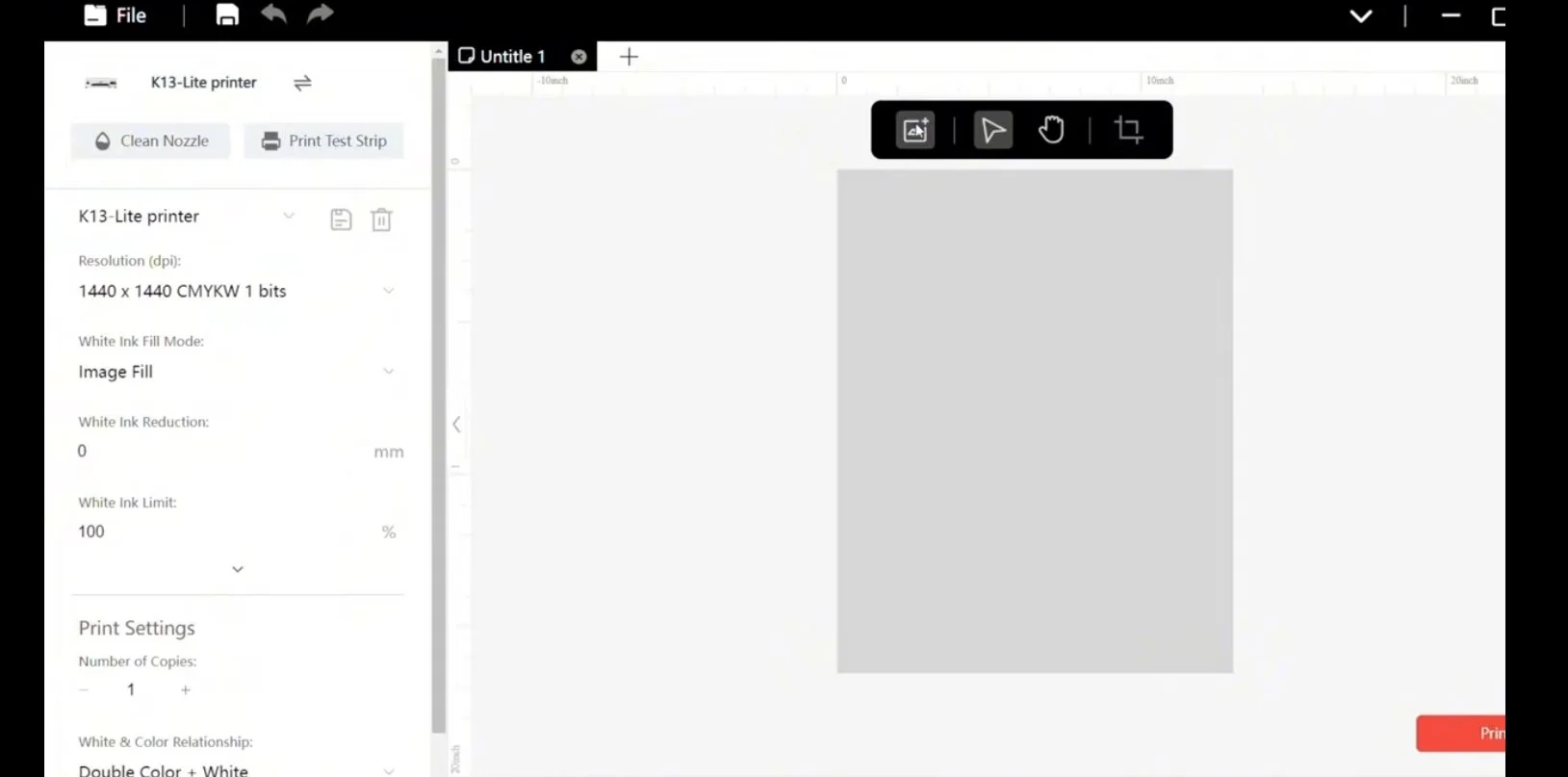

For the Procolored K13 Lite:

the printer connects to your computer via USB

a dongle needs to be plugged in

designs are uploaded into the Procolored software

The software itself is fairly basic — it’s mainly for:

uploading designs

resizing

positioning them on the film

You can print multiple designs on one sheet, which is great for efficiency.

Making the Transfers

Making HTV Transfers

For HTV, the process looks like this:

Place vinyl on the mat

Cut each colour layer separately

Weed every layer by hand

Weeding can be:

time-consuming

wasteful (especially with small cut-outs)

fiddly around letters and details

You also need to be careful not to leave tiny vinyl scraps on the carrier sheet, as these can accidentally transfer to your t-shirt.

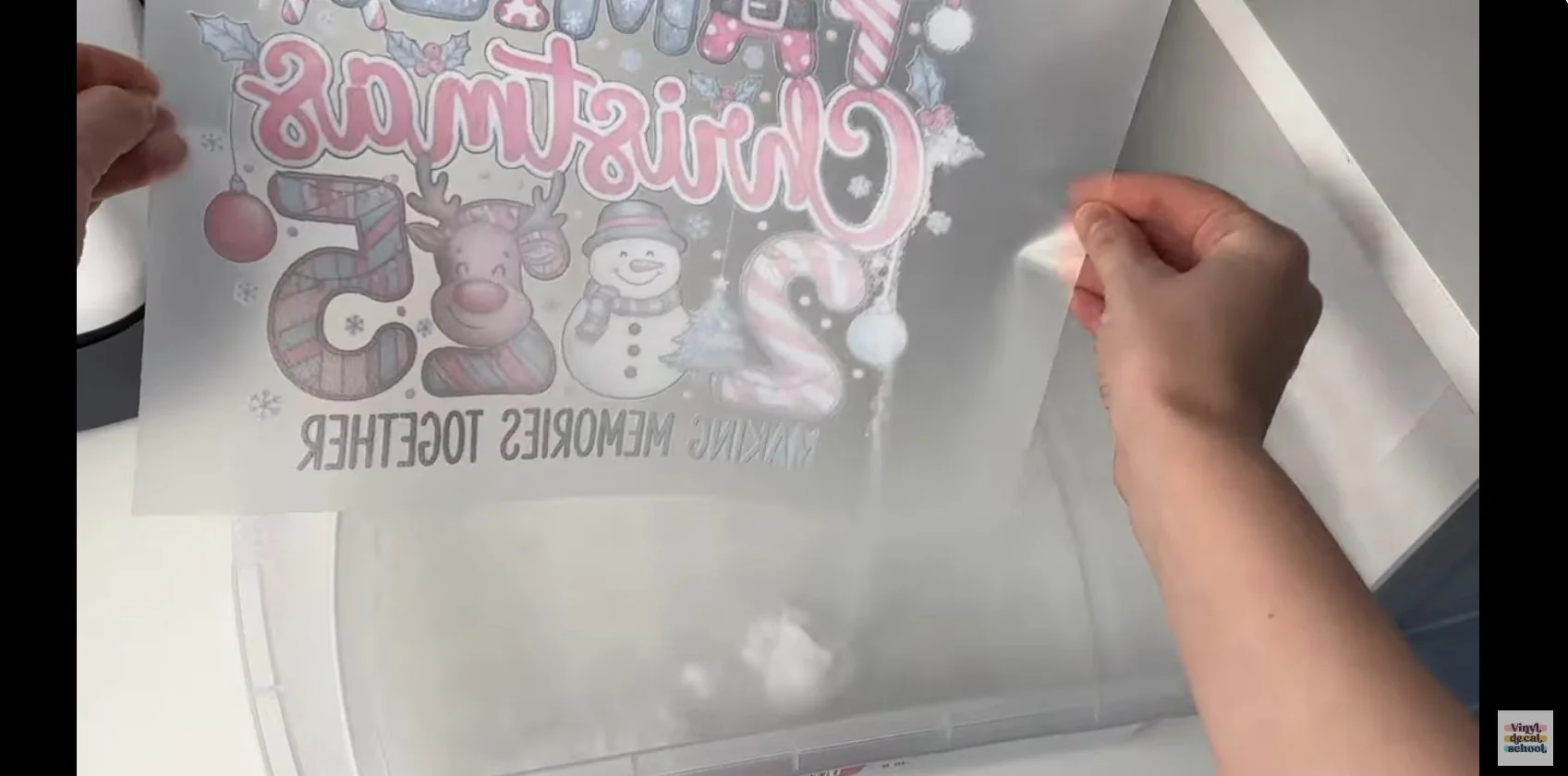

Making DTF Transfers

With DTF:

Turn on the printer and let it warm up

Send the design to print

Trim the printed film

Apply DTF powder to the adhesive side

Shake off excess powder

Cure the design in a smokeless oven

The curing stage took around 200 seconds, and you’re looking for an “orange peel” texture on the back — that’s how you know it’s done.

Both HTV and DTF are technically two-step processes, but the time involved depends heavily on design complexity and machine warm-up times.

Applying to T-Shirts

I applied both designs to 100% cotton t-shirts.

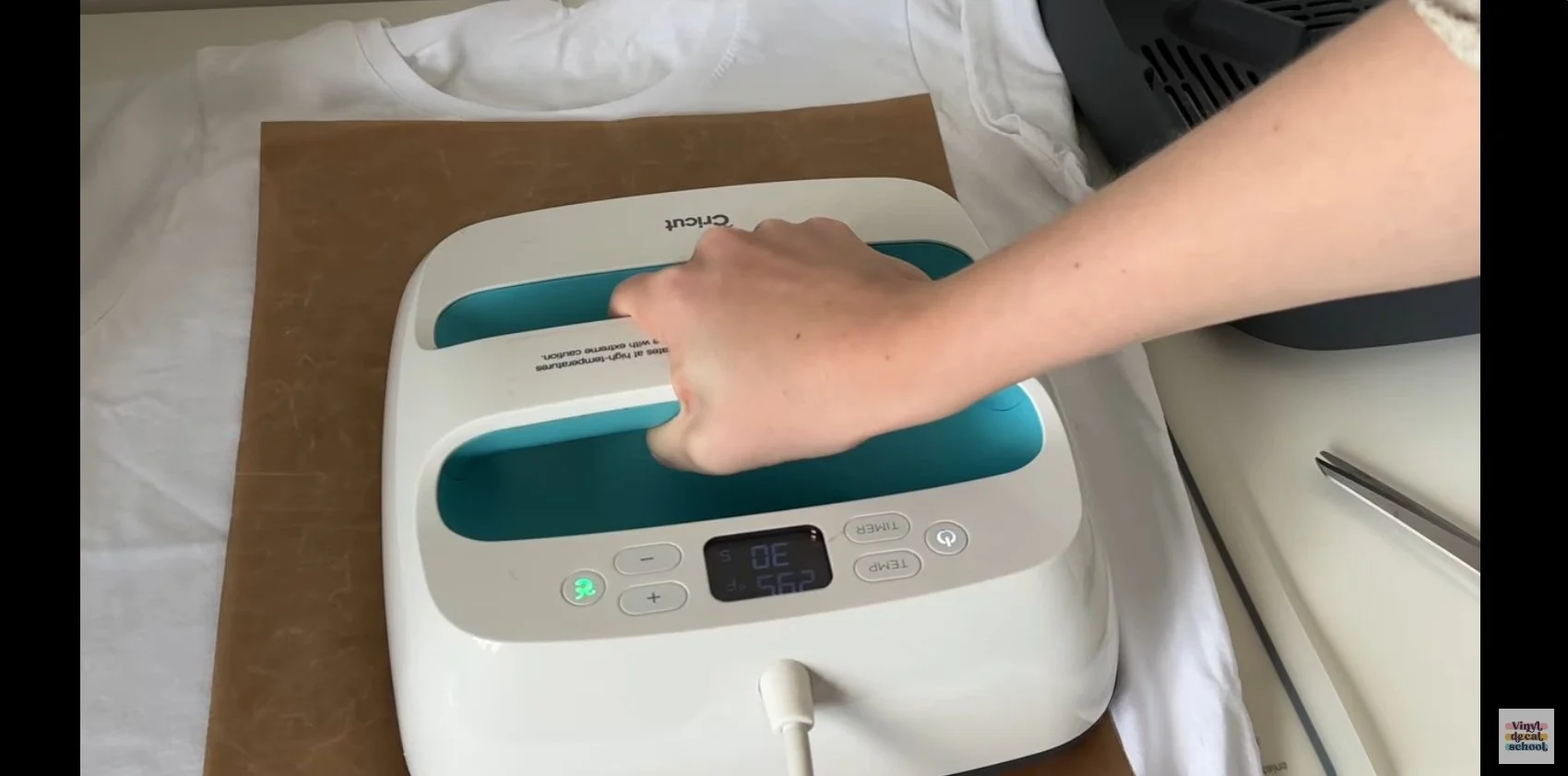

Applying HTV

Line up first layer

Cover with a Teflon sheet

Heat press

Warm peel

Repeat for each layer

HTV layering requires precision and patience, but metallic vinyls do give a really beautiful sheen.

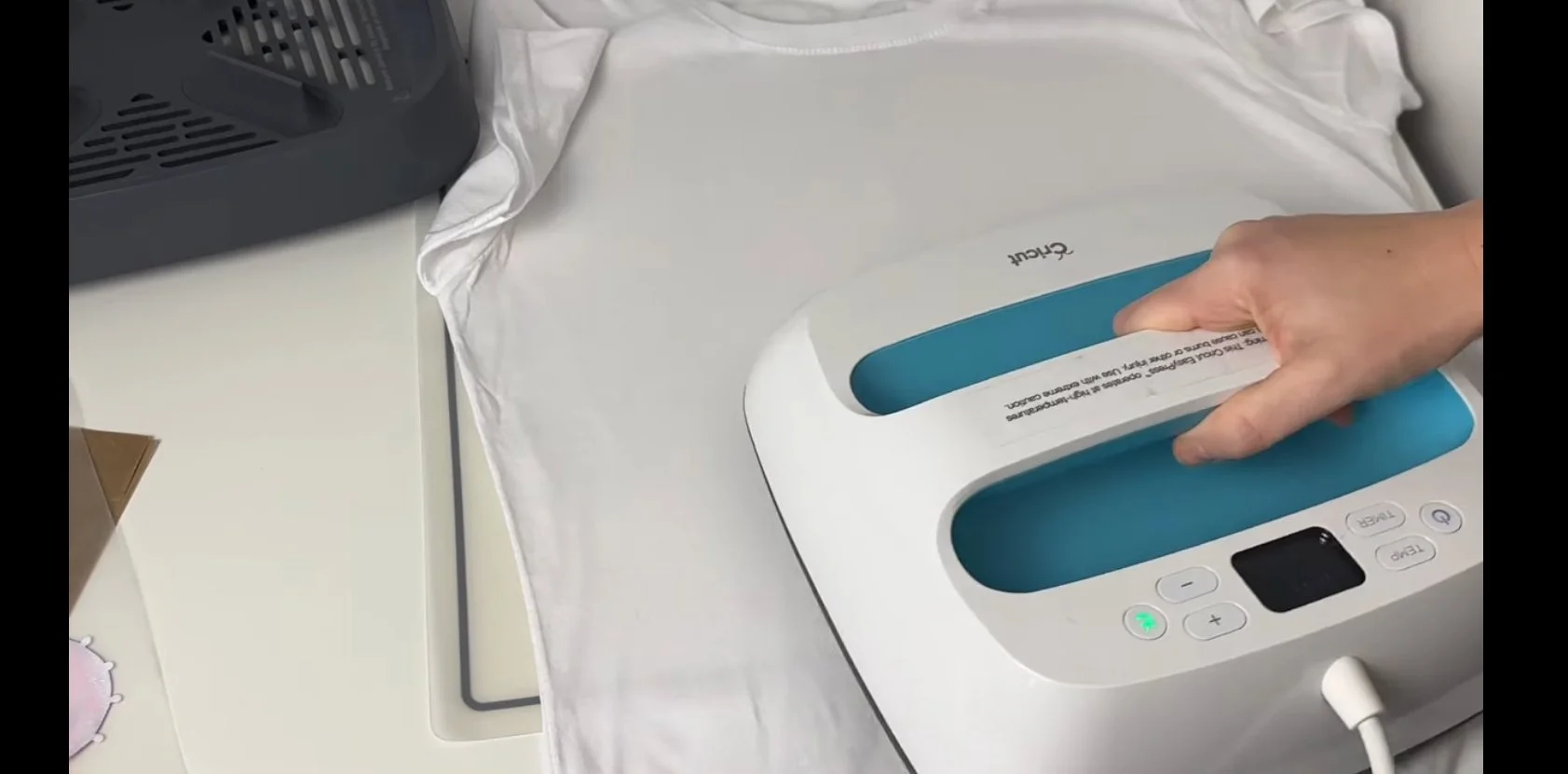

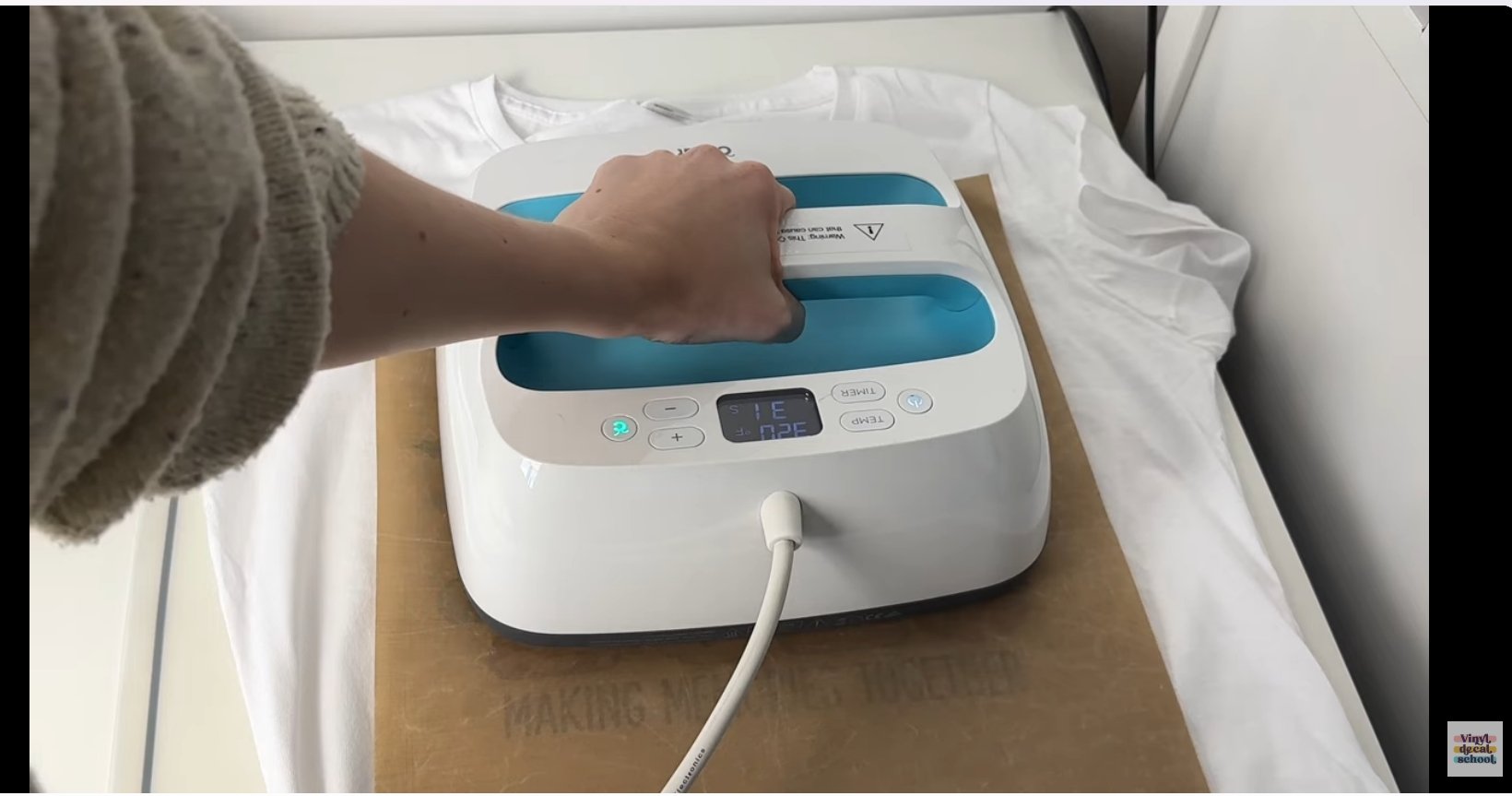

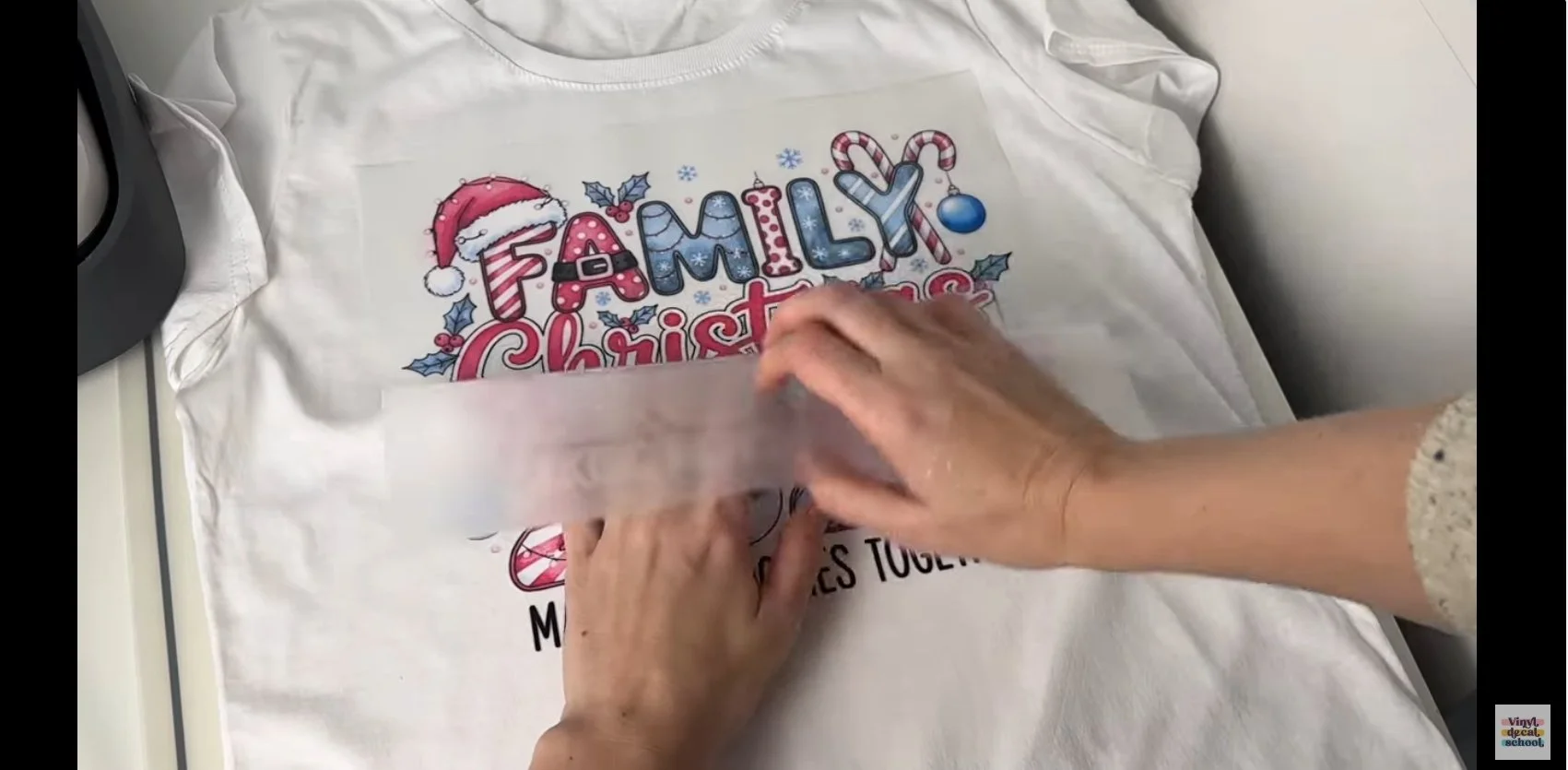

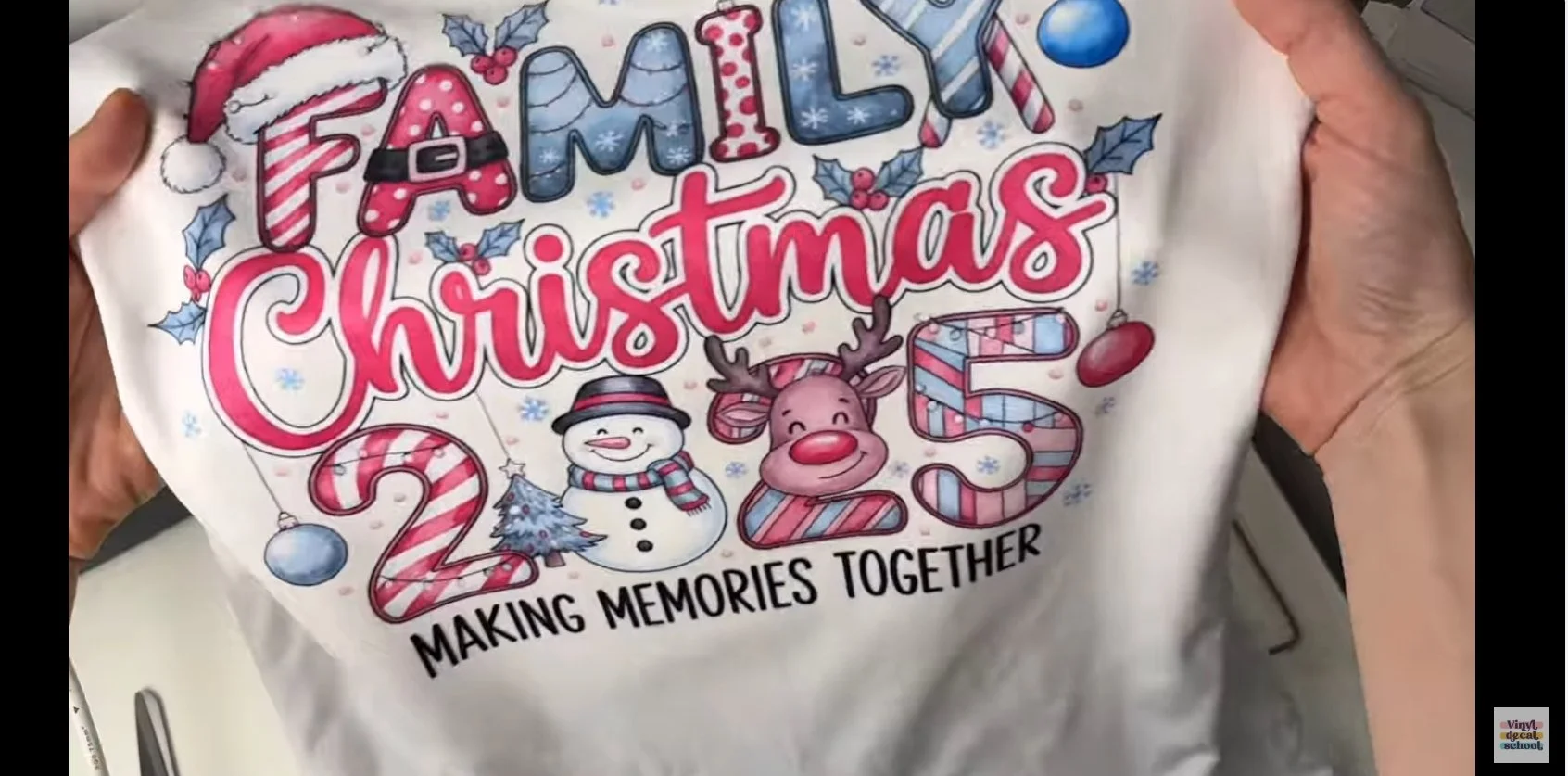

Applying DTF

Pre-press the shirt

Position the transfer

Cover and press

Allow to cool fully

Cold peel the film

The Procolored printer included a cooling block to speed this up. Some very small details were slightly trickier to peel, which is something to consider when designing.

If you plan to make large volumes of shirts with either method, a swing heat press is highly recommended for:

even pressure

consistent adhesion

faster production

The Wash Test

Both shirts were:

washed inside out

on a 30°C cycle

air dried (never tumble dried)

HTV Results

metallic HTV began peeling

some edges lifted

red vinyl held better than the metallic

HTV can last well, but durability depends heavily on:

vinyl quality

pressure consistency

heat accuracy

DTF Results

looked almost identical to pre-wash

small details stayed intact

only a tiny edge lifted

Overall, DTF performed significantly better in this wash test.

Pros & Cons Summary

HTV (Iron-On Vinyl)

Pros

Accessible for beginners

Lower startup cost

Specialty finishes (glitter, puff, metallic)

Cons

Limited to single-colour or layered designs

Time-consuming weeding

Can be less durable over time

DTF (Direct to Film)

Pros

Full-colour designs

No weeding

Excellent durability

Ideal for bulk production

More competitive for modern designs

Cons

Higher upfront machine cost

Some maintenance required (though minimal on the K13 Lite)

Customer support helped me quickly fix a colour issue using provided tools, and after that the prints were vibrant and accurate.

Cost Comparison (UK Example)

HTV Setup

Cutting machine: ~£270

HTV vinyl: ~£5.95 per metre

10 colours + shipping: ~£67

Costs scale up quickly with layered or specialty vinyls.

DTF Setup

Procolored K13 Lite: ~£2242 (on deal)

Includes ink, powder and film

100m film roll (much longer than vinyl rolls)

~400 A4 prints per ink set (approximate)

Although the upfront cost is much higher, DTF becomes cheaper per print over time — especially for multi-colour designs.

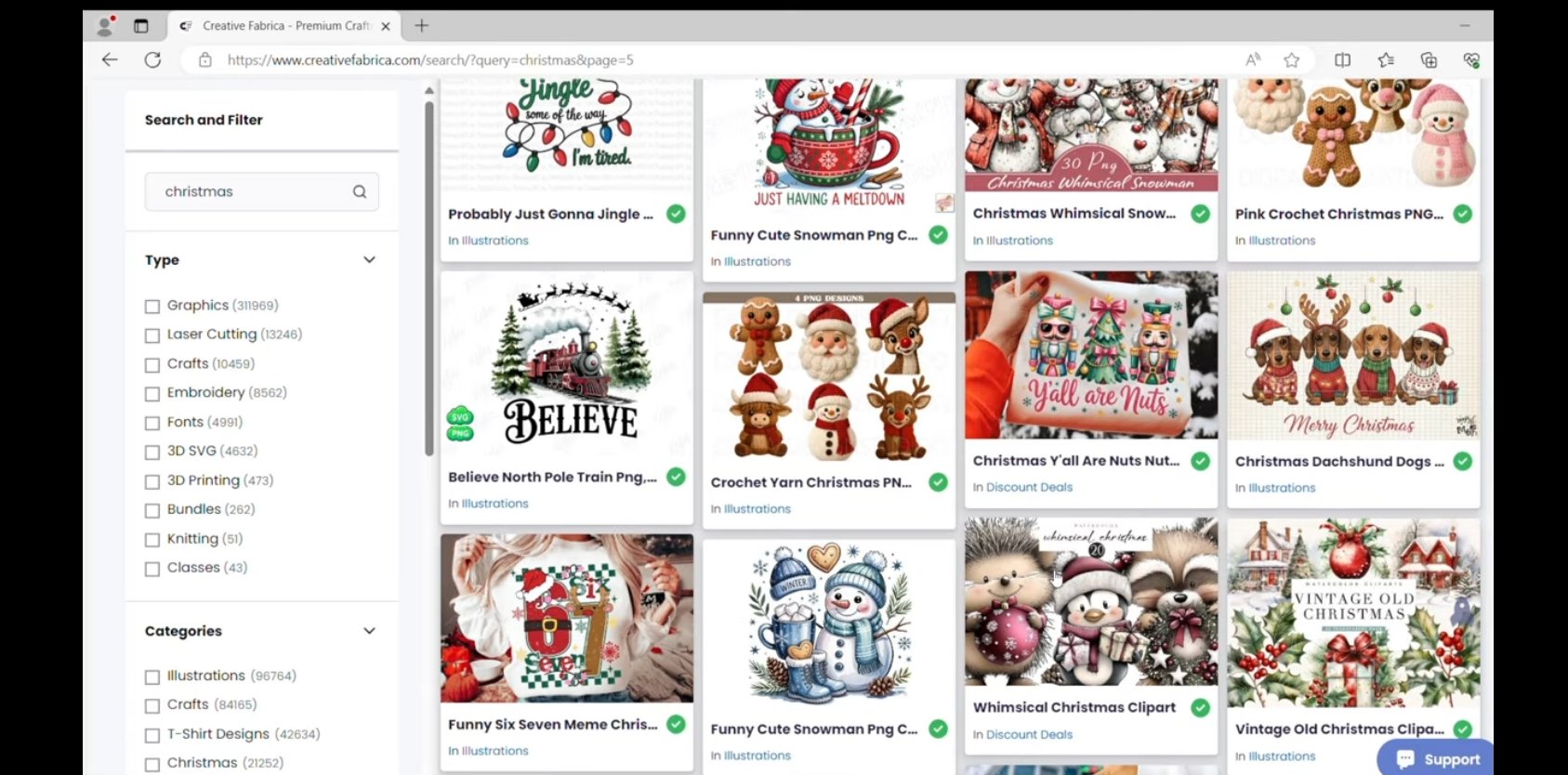

And when you look at marketplaces like Etsy, most best-selling t-shirts are already full colour, which DTF makes much easier to compete with.

So… which should you choose?

Ask yourself:

Who are my customers?

Do I need full-colour designs?

Am I selling one-off shirts or bulk orders?

What can I realistically afford right now?

If you’re just starting out, one smart option is to:

order DTF prints from a supplier

test demand

then invest in a printer later

Final Thoughts

There’s no “one size fits all” answer.

HTV is brilliant for beginners, logos, and textured designs

DTF is ideal for scaling, durability, and competing visually

So… are you Team HTV or Team DTF?

Let me know what you’d choose, and why! If you found this helpful, keep an eye out for more craft business tutorials, comparisons, and honest reviews.